Taiwan RoHS Information

This section provides the Taiwan RoHS information for switches this guide covers.

:

:

This section provides the Taiwan RoHS information for switches this guide covers.

:

:

This section discusses the process for replacing switch components.

You must ensure that at least one of the secondary grounding pads on the chassis's front panel is connected to the data center ground. While working on the switches, select grounded, anti-static wrist straps connected to one of the attach points on the switch for grounding yourself and preventing ESD damage to the switch.

The switches support AC or DC Power supplies. The switches ship with several populated slots depending on the switch model. Empty slots are covered with a blank. To add a new power supply in one of the available slots, remove the blank covering the slot before inserting a new power supply. The following steps are required for ESD protection when adding or replacing power supplies.

Perform the following steps to install an AC power supply.

Make sure to remove the ground connection last when removing power.

Perform the following steps to install a DC power supply.

The fabric and fan modules are hot-swappable. They are accessible from the rear of the switch (Rear Panel). Consider that the module you insert is compatible with the switch and the module you are replacing. If your switch supports one, perform the following steps to remove and replace a fabric and fan module or a fan-only module.

Perform the following steps to install the module.

This product must be grounded. Never defeat the ground conductor or operate the equipment without as a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician if you are uncertain that suitable grounding is available. When installing or replacing this product, the ground connection must always be made first and disconnected last, and the person performing the task(s) must wear a grounded ESD (anti-static) strap.

The supervisor modules are hot-swappable. They are accessible from the front of the switch. Consider that the module you insert is compatible with the switch and the module you are replacing. Use the following procedure to remove and replace a supervisor module. For the supervisor module locations for your device, refer to the Front Panel.

Perform the following steps to install the module.

The linecards are hot-swappable. They are accessible from the front of the switch. Consider that the linecard you are inserting is compatible with the switch and the linecard that you are replacing.

Use the following procedure to remove and replace a linecard. If you add a new linecard, remove the blank from the linecard slot and install the new linecard. For the linecard locations on your switch, refer to the Front Panel.

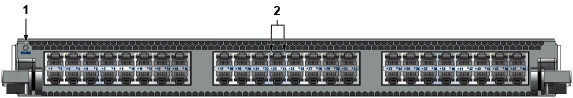

This section displays the linecards supported by modular switches covered by this guide.

The 36-port QSFP+ linecard has 36 QSFP+ ports, allowing for a high degree of flexibility in a mixed 10G/40G network. All QSFP+ ports can operate as either a single 40Gb Ethernet port or quad 10Gb Ethernet ports with up to 36 port of 40G or 144 ports of high-density 10G.

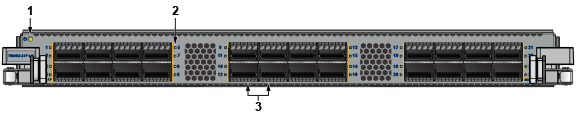

| 1 | Status LED | 2 | 40G port LEDS |

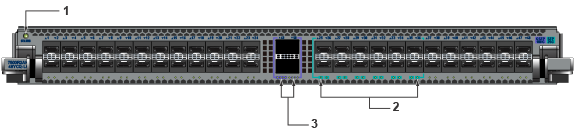

The 48-SFP+ and 2-port 100GbE MXP linecard provides a flexible combination of 48 ports of SFP+ and 2 MPO ports for up to 72 10Gb Ethernet ports. The two 100G MTP/MPO ports provide 100G capability using Arista Multi-speed Ports (MXP) with integrated optics. MXP ports use 100GBASE-SR10 (Short Range) transceivers and are fully compatible with any standards-compliant 100GBASE-SR10 ports. Each MXP port can be easily configured as a single 100Gb, triple 40Gb, or twelve 10Gb Ethernet.

| 1 | Status LED | 2 | 10G port LEDS | 3 | MXP port LEDS |

The 48-port 1/10GbE SFP+ linecard has 48 SFP+ ports. Having 48 SFP+ ports allows this linecard the flexibility to utilize any existing Arista SFP+ optic or direct attach cables and to support both 1Gb and 10Gb speeds.

| 1 | Status LED | 2 | 10G port LEDS |

The 12 x 100G MTP/MPO linecard provides high-density 100G using Arista Multi-speed Ports (MXP) with embedded optics. The MXP ports use 100GBASE-SR10 (Short Range) transceivers and are fully compatible with any standards-compliant 100GBASE-SR10 ports. Each MXP port can be enabled in single 100Gb, triple 40Gb, or twelve 10Gb Ethernet modes for up to 12 – 100Gb, 36 – 40Gb, and 144 – 10Gb Ethernet ports per linecard. Since each MXP port comes with integrated optics, no external transceivers are required for this linecard.

| 1 | Status LED | 2 | MXP port LEDS |

The 6 x 100G CFP2 linecard provides high-performance 100G using industry-standard CFP2 optics that are hot pluggable. The CFP2 form factor design allows long-haul optics that are approximately 50% smaller than the CFP optic. As a result, the CFP2-based linecards allow for up to 6 ports per linecard, which increases overall system density. The CFP2 form factor allows 100GbE optics to be installed using 10x10 and 2x40 modes with a choice of 10/40/100GbE.

| 1 | Status LED | 2 | CFP2 port LEDS |

The 12 x 100G QSFP100 linecard provides high-density 100G using industry-standard QSFP100 optics. The QSFP100 form factor is identical to the size of the 40G QSFP+, allowing for either 40GbE or 100GbE optics to be installed for a dual speed choice of 40/100GbE on all ports. With 12 ports of 100GbE, the card allows each port to operate in a choice of 4 x 10GbE (using 40GbE optics), 40GbE, or 100GbE.

| 1 | Status LED | 2 | 40/100G port LEDS |

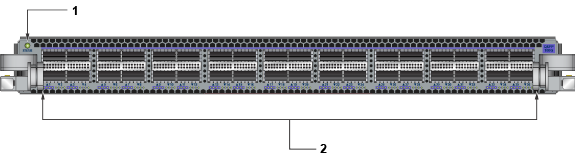

The 48-port RJ45 10GBASE-T wire-speed linecard has 48 RJ45 ports that support 10Gb speeds.

| 1 | Status LED | 2 | 10G port LEDS |

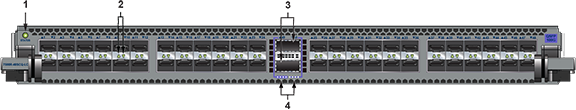

The 48-SFP+ and 2-port 100GbE QSFP linecard provides a flexible combination of 48-SFP+ and 2-QSFP100 ports for up to 56 10Gb Ethernet ports. The two 100G QSFP100 ports allow 1x 100G, 1x40G, or 4x10G capability.

| 1 | Status LED | 3 | 100G port LEDs |

| 2 | Port LEDS | 4 | 100G port LEDs |

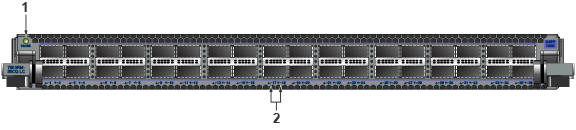

The 36-port QSFP100 linecard allows for high flexibility in a mixed 10G/40G/100G environment. All 36 ports can operate as a single 100Gb or 40Gb Ethernet port. A wide range of additional interface speed flexibility is possible, with all ports supporting 4 x 10G Ethernet, 4 x 25G Ethernet, or 2 x 50G Ethernet. This flexibility allows for a choice of 5 speeds on all ports, simple migration from 10G to 100G, and a wide range of combination

| 1 | Status LED | 2 | Port LEDS |

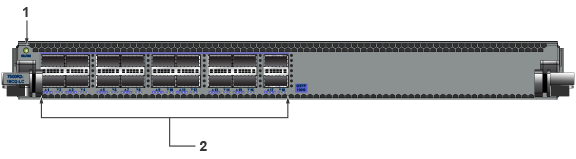

The 36-port QSFP+ linecard allows for a wide range of flexibility in a mixed 10G/40G environment. All QSFP+ ports can operate as either a single 40Gb Ethernet port. Additional interface flexibility is possible, with up to 24 ports supporting 4x10G mode and 6 ports of 1x100G mode. These interface speed choices allow for simple migration from 10G to 100G and various possible combinations.

| 1 | Status LED | 3 | 100G ports |

| 2 | 100G ports | 4 | Port LEDs |

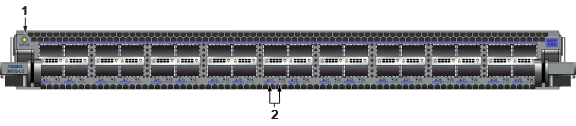

The 36-port QSFP100 linecard allows 36 x 100G of wire-rate performance with integrated MACsec on every port. Each packet processor connects to 6 ports of 100G with 4GB of deep packet buffer; the 100G ports support either QSFP100 (100G) or QSFP+ (40G).

| 1 | Status LED | 2 | 100G MACsec port LEDS |

The 18-port QSFP100 linecard allows 18 x 100G of wire-rate performance.

| 1 | Status LED | 2 | 100G port LEDS |

The 36-port QSFP100 linecard allows 36 x 100G of wire-rate performance.

| 1 | Status LED | 2 | Port LEDS |

The 36-port QSFP100 linecard allows 36 x 100G of wire-rate performance.

| 1 | Status LED | 2 | 100G ports |

The 36-port QSFP100 linecard allows 36 x 100G of wire-rate performance.

| 1 | Status LED | 2 | 100G port LEDs |

The 36-port QSFP100 linecard allows 36 x 100G of wire rate performance.

| 1 | Status LED | 2 | 100G port LEDs |

The 36-port QSFP100 linecard allows 36 x 100G of wire-rate performance.

| 1 | Status LED | 2 | 100G ports |

The linecard has 2 x 100G and 12 x 25G ports.

| 1 | Status LED | 2 | 25G ports | 3 | 100G ports |

The 8-port tunable coherent DWDM with MACsec linecard allows 200G of long-haul data performance.

| Status LED | 2 | CFP2 port |

The linecard can support up to 36 100G or 72 50G ports.

| 1 | Status LED | 2 | 100G port LEDS |

The linecard can support 24-wire speed 400G OSFP ports or up to 96 100G ports with breakout cables and optics. The linecard can support 10G, 25G, and 50G speeds with optics or cables.

| 1 | Status LED | 2 | 400G port LEDs | 3 | 400G ports |

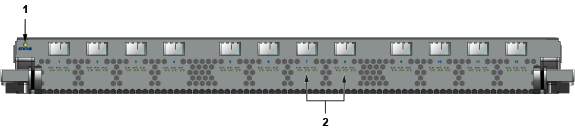

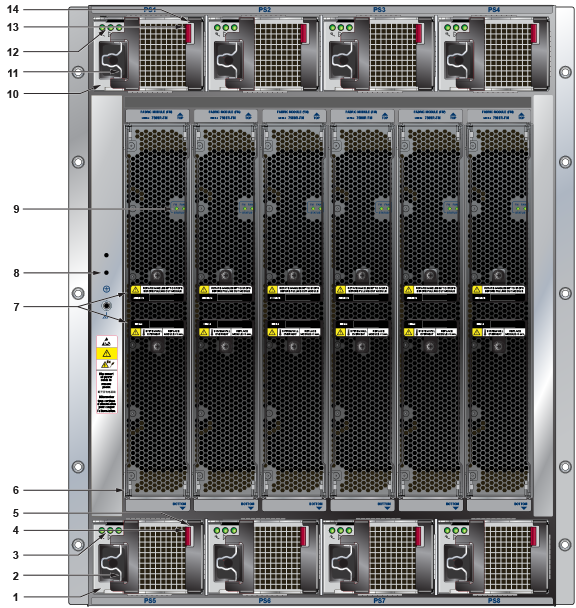

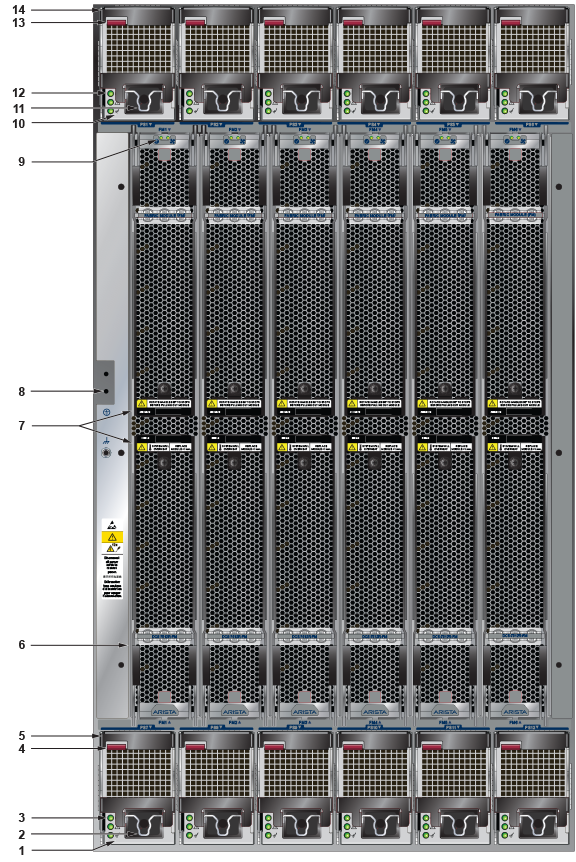

This section displays the rear panel of all switches covered by this guide.

| 1 | Fabric module screw | 4 | Chassis ground | 7 | Ground |

| 2 | Fabric module ejector handle | 5 | PSU | 8 | Ejector button |

| 3 | Fabric module status LEDs | 6 | Release lever | 9 | Status LEDs |

| 1 | PSU bottom row (PS5) | 6 | Fabric module | 11 | Power cord clip (optional) |

| 2 | Power cord clip (optional) | 7 | Fabric module ejector handles | 12 | Status LEDs (PS1) |

| 3 | Status LEDs (PS5) | 8 | Chassis ground (secondary) | 13 | Ejector button |

| 4 | Ejector button | 9 | Fabric module status LEDs | 14 | Release lever |

| 5 | Release lever | 10 | PSU top row (PS1) |

| 1 | PSU bottom row (PS7) | 6 | Fabric module | 11 | Power cord clip (optional) |

| 2 | Power cord clip (optional) | 7 | Fabric module ejector handles | 12 | Status LEDs (PS1) |

| 3 | Status LEDs (PS7) | 8 | Chassis ground (secondary) | 13 | Ejector button |

| 4 | Ejector button | 9 | Fabric module status LEDs | 14 | Release lever |

| 5 | Release lever | 10 | PSU top row (PS1) |

| 1 | Power domain 2 (PSU11-PSU20) | 4 | Fabric module |

| 2 | Fabric module ejector handles | 5 | Fabric module status LEDs |

| 3 | Chassis ground (secondary) | 6 | Power domain 1 (PSU1-PSU10) |

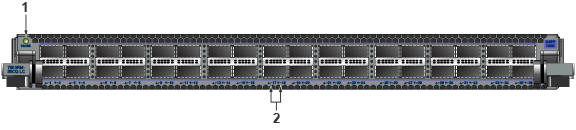

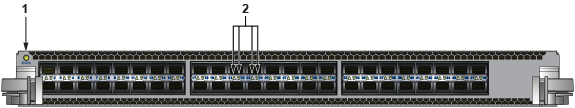

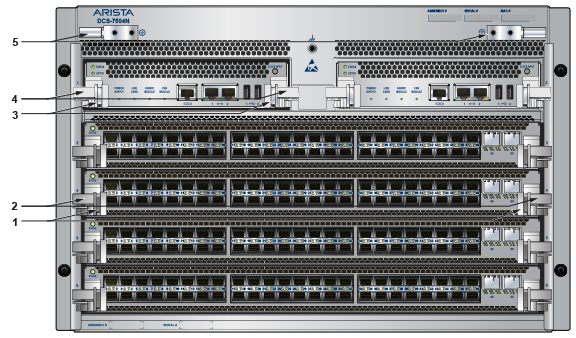

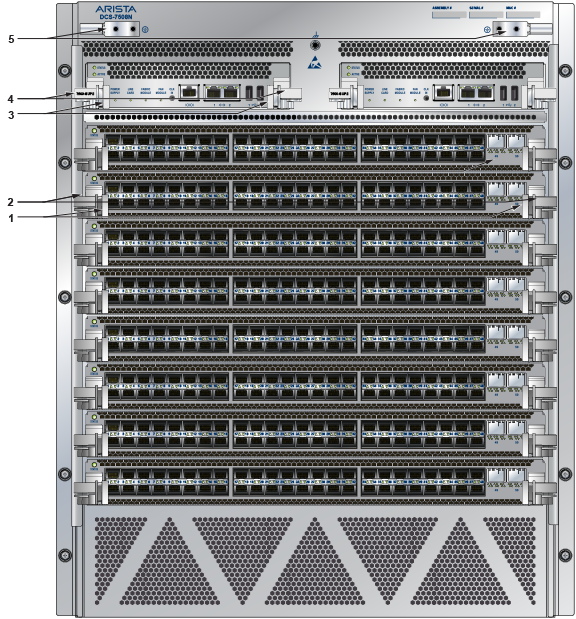

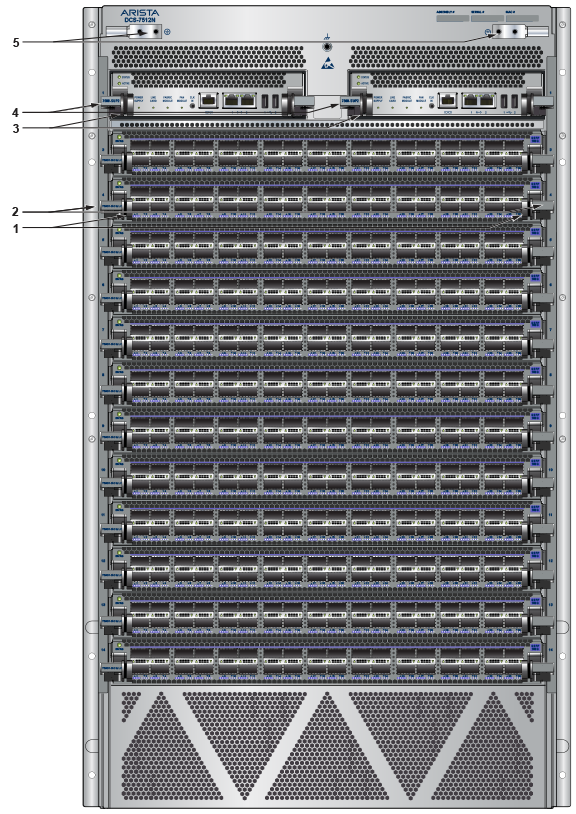

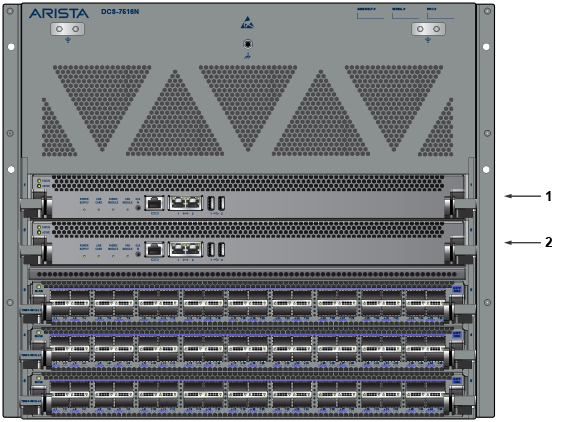

This section displays the front panel of all switches this guide covers.

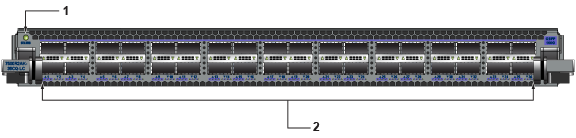

| 1 | Linecard ejector button | 3 | Supervisor ejector button | 5 | Ground |

| 2 | Linecard ejector handle | 4 | Supervisor ejector handle |

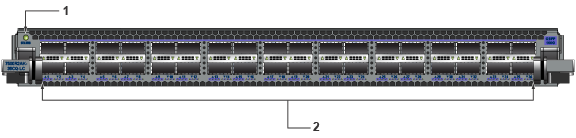

| 1 | Linecard ejector button | 3 | Supervisor ejector button | 5 | Ground |

| 2 | Linecard ejector handle | 4 | Supervisor ejector handle |

| 1 | Linecard ejector button | 3 | Supervisor ejector button | 5 | Ground |

| 2 | Linecard ejector handle | 4 | Supervisor ejector handle |

%20(1).png)

| 1 | Linecard ejector button | 3 | Supervisor ejector button | 5 | Ground |

| 2 | Linecard ejector handle | 4 | Supervisor ejector handle |

Each switch has an accessory kit that contains the parts required to install the switch. Table 1 provides further details on the accessory kit for each switch. The following sections in the chapter list the installation parts provided by the accessory kit in more detail.

| 7504N | 7508N | 7512N | 7516N | |

|---|---|---|---|---|

| Common cables and accessories | Included | Included | Included | Included |

| Two-Post rack mount parts | Included | Included | N/A | N/A |

| Four-post rack mount kit for 4-slot and 8-slot chassis | Included | Included | N/A | N/A |

| Four-post rack mount kit for 12-slot and 16-slot chassis | N/A | N/A | Included | Included |

| Number of Power cords (C19 - C20 type) included | 4 | 6 | 8 | 12 |

All provided power cables are for use only with Arista products.

Câbles d’alimentation doivent être utilisés uniquement avec des produits de Arista.

| Quantity | Description |

|---|---|

| 2 | RJ-45 Patch Panel Cables, 2 meters |

| 2 | RJ-45 to DB9 Adapter Cable, 2 meters |

One 2-page document.

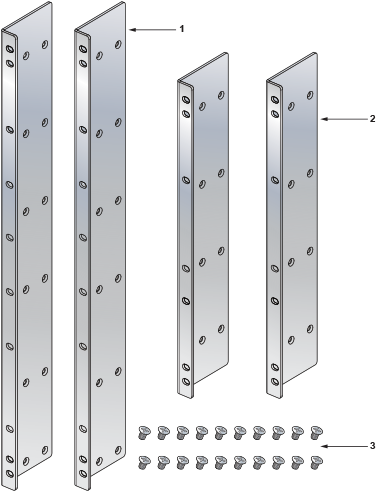

The following section lists the parts provided for the two-post rack mount installation.

| Quantity | Description |

|---|---|

| 2 | Center-mount brackets |

| 20 | M4x8 pan-head Phillips screws |

| 1 | Center-mount brackets (DCS-7508N only) |

| 2 | Center-mount brackets (DCS-7504N only) |

| 3 | M4x8 pan-head Phillips screws |

The following sections list the parts provided in the accessory kit for four-post rack mount installations of the 4-slot and 8-slot chassis.

| Quantity 1 | Description |

|---|---|

| 2 | Front brackets. |

| 4 | Shelf supports. |

| 2 | Back brackets. |

| 1 | Left shelf. |

| 1 | Right shelf. |

| 11 (17) | M6x16 pan-head Phillips screws. |

| 7 (13) | M6 Hex Nuts. |

| 3 (9) | M6 Cage Nut Square Hole Racks. |

| 5 | M5 Hex Nuts. |

| 11 (17) | M5 pan-head Phillips screws. |

| 5 | #12-24 Hex Nuts. |

| 11 (17) | #12-24 pan-head Phillips screws. |

| 5 | #10-32 Hex Nuts. |

| 11 (17) | #10-32 pan-head Phillips screws. |

| 1 | Adjustable Wrench |

1 Quantities in parentheses “()” are for the 7508N where the quantities differ from the 7504N.

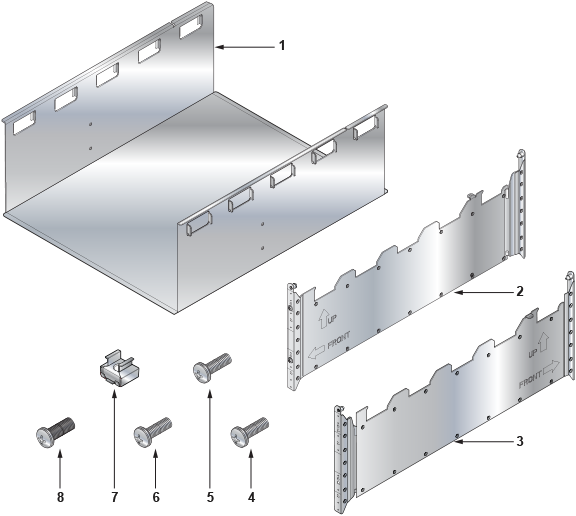

| 1 | Front brackets (DCS-7504N only) | 4 | Left shelf | 7 | M6 hex nuts |

| 2 | Front brackets (DCS-7508N only) | 5 | Right shelf | 8 | M6x16 pan-head Phillips screws |

| 3 | Shelf support | 6 | M6 cage nuts | 9 | Back brackets (not needed for racks with threaded holes) |

The following sections list the parts provided in the accessory kit for four-post rack mount installations of the 12-slot and 16-slot chassis.

| Quantity | Description |

|---|---|

| 1 | Shelf (or cradle) |

| 1 | Left shelf support |

| 1 | Right shelf support |

| 25 | M6 cage nuts square hole |

| 25 | M6x16 pan-head Phillips screws |

|

25 |

M5x16mm pan-head Phillip screws |

| 25 | 12-24x5/8 pan-head Phillip screws |

| 27 | 10-32x5/8 pan-head Phillip screws |

| 1 | Cradle | 4 | #10-32x5/8 pan-head Phillip screws | 7 | M6 cage nuts (for square hole racks) |

| 2 | Left telescoping arm | 5 | #12-24x5/8 pan-head Phillip screws | 8 | M6x16 pan-head Phillips screws |

| 3 | Right telescoping arm | 6 | M5x16mm pan-head Phillip screws |

This section discusses the following topics:

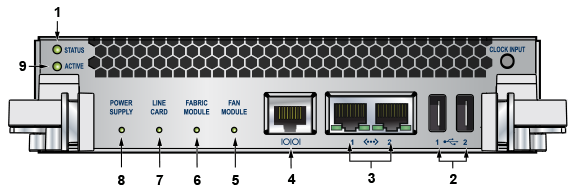

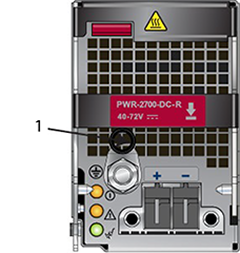

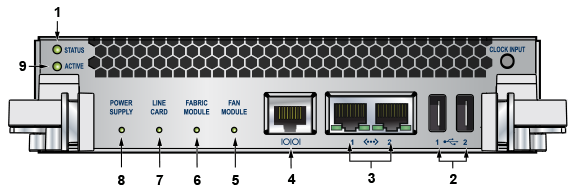

While the front panel of each switch can house two supervisors, switch operations require only one. Supervisors display switch component status and contain Ethernet management and console ports.

| 1 | Status LED | 2 | USB ports | 3 | Ethernet management ports |

| 4 | Serial console port | 5 | Fan module status LED | 6 | Fabric module status LED |

| 7 | Linecard status LED | 8 | Power supply status LED | 9 | Active LED |

| 1 | Status LED | 2 | USB ports | 3 | Ethernet management ports |

| 4 | Serial console port | 5 | Clock input port (optional) | 6 | Fan module status LED |

| 7 | Fabric module status LED | 8 | Linecard status LED | 9 | Power supply status LED |

| 10 | Active LED |

| 1 | Status LED | 2 | USB ports | 3 | Ethernet management ports |

| 4 | Serial console port | 5 | Clock input port (optional) | 6 | Fan module status LED |

| 7 | Fabric module status LED | 8 | Linecard status LED | 9 | Power supply status LED |

| 10 | Active LED |

The Status and Active LEDs are located on the left side of the Supervisor Module. Table 1 interprets the states of these two LEDs.

| LED Name | LED State | Supervisor State |

|---|---|---|

| Status | Off | No power, failed, or improperly inserted. |

| Green | Operating normally. | |

| Red | Supervisor failed. | |

| Active | Off | Not active. |

| Green | Active and controlling the switch. |

LEDs located below the vents and left of the input ports display summary indicators for power supplies, fabric modules, fans, and linecards. Table 2 interprets the states of these indicators. When error conditions are indicated, refer to LEDs on the specified modules to determine the condition’s source.

| LED Name | LED State | Module State |

|---|---|---|

| Power Supply, Linecard Fabric Module Fans | Off | No modules are present or powered. |

| Green | All powered modules are operating normally. | |

| Red | One or more components failed. |

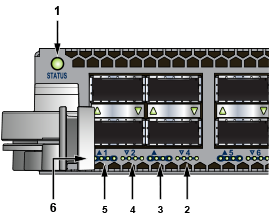

Each linecard module provides one status LED plus LEDs for each port on the card. The figures in Linecards indicate the location of the LEDs on each linecard.

| 1 | Status LED | 2 | QSFP port 4 LEDs | 3 | QSFP port 3 LEDs |

| 4 | QSFP port 2 LEDs | 5 | QSFP port 1 LEDs | 6 | 10G / 40G /100G QSFP port LEDs |

Table 3 interprets the states of the status LED.

| LED State | Status |

|---|---|

| Off | Linecard not inserted. |

| Green | Linecard operating normally. |

| Yellow | Linecard administratively shut down. |

| Red | Linecard has failed. |

The linecard provides LEDs for each port module socket:

Table 4 interprets the port LED states.

| LED State | Status |

|---|---|

| Off | Port link is down. |

| Green | Port link is up. |

| Yellow | Port is disabled in software. |

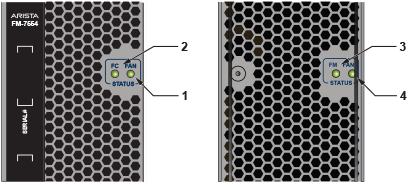

Fabric Status LEDs are on fan-fabric modules. The Rear Panel displays the position of these LEDs on the rear of each switch. Figure 5 display fan status and fabric status LEDs on the switch.

| 1 | Fan status LED | 3 | Fabric status LED |

| 2 | Fabric status LED | 4 | Fan status LED |

| 1 | Fabric status LED | 2 | Fan status LED |

Table 5 interpret the fan and fabric status LED states.

| LED State | Status |

|---|---|

| Off | Module inserted, but the status is unknown. |

| Green | Module operates normally |

| Red | Module failed |

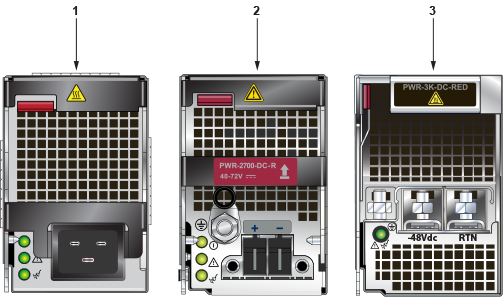

The power supply LEDs are on the power supply modules. The positions of the LEDs are on the rear of each switch. Figure 7 display all the power supply modules supported on the 7500N.

Table 6 interprets the power supply set up for LED status indicators.

| Power Supply State | LED Name | PWR-3KT-AC-Red | PWR-2700-DC-R | PWR-3K-DC-Red |

|---|---|---|---|---|

| Input power present Normal Operation | DC Good Fault Vin Good | Green Off Green | Green Off Green | Green |

| Input power present Main output off | DC Good Fault Vin Good | Off Off Green | Off Off Green | Blinking Green |

| Input power present Power Supply Fault | DC Good Fault Vin Good | Off Blinking Amber Green | Off Blinking Amber Green | Blinking Amber, 1 sec on, 1 sec off |

| No Input Power Supply installed in chassis | DC Good Fault Vin Good | Off Off Off | Off Off Off | Off |

| Input power present Supply not seated in chassis | DC Good Fault Vin Good | Off Off Blinking Green | Off Off Off | Blinking Amber, 0.5 sec on/off |

Before you begin, refer to the Arista Networks document Compliance and Safety Guide, available at https://www.arista.com/en/support/product-documentation.

Power down the switch. Remove all power cords from the power inlets.

Mettez le commutateur: Retirez tous les cordons d'alimentation des prises d'alimentation

Installation of this equipment must comply with local and national electrical codes. Consult with the appropriate regulatory agencies and inspection authorities to ensure compliance if necessary.

Installation de cet équipement doit être conformes aux codes électriques locaux et nationaux. Si nécessaire, consulter les organismes de réglementation appropriés et des autorités de contrôle pour assurer la conformité.

Many configurations will require additional power supplies.

Nombreuses configurations exigera des alimentations supplémentaires.

All power supply slots must be filled with either a power supply or blank to ensure proper airflow.

Tous les emplacements d'approvisionnement de puissance doivent être remplis avec une alimentation ou vide pour assurer un débit d'air appropriée.

Read all installation instructions before connecting the system to the power source.

Lire toutes les instructions d'installation avant de brancher le système à la source d'alimentation.

The 7500N chassis requires the connection of at least two operating power supplies in the top row to active circuits.

Each power supply includes a fan that maintains proper power supply temperature and cools the supervisor modules. The appendices display the location of components for all switches described in this guide.

Figure 1 shows the supported power supplies for the 7500N family of switches.

| 1 | PWR-3KT-AC-Red | 2 | PWR-2700-DC-R | 3 | PWR-3K-DC-Red |

The Front Panel displays the secondary grounding pads' location on the switch chassis's front panel. After mounting the switch into the rack, connect at least one of the secondary grounds to the data center ground. After the switch is grounded, ESD wrist straps can be grounded by connecting them to one of the attach points.

Grounding wires and grounding lugs are not supplied. Wire size should meet local and national installation requirements. Commercially available 2 or 4 AWG wire is recommended for installations in the U.S.

À la terre et de mise à la terre fils cosses ne sont pas fournis. Calibre des fils doit satisfaire des exigences de l'installation locale et nationale. Disponible dans le commerce 2 ou 4 AWG fil est recommandé pour les installations aux États-Unis.

This equipment must be grounded. Never defeat the ground conductor. This unit requires over-current protection.

Cet équipement doit être mis à la terre. Ne jamais modifier le conducteur de terre. Cet appareil nécessite de protection contre les surintensités.

Secondary Grounding wires, lugs, and screws (M4 x 0.7) are not supplied.

Secondaire à la terre, câbles, cosses et vis (M4 x 0.7) ne sont pas fournis.

Secondary ground locations on the switches are displayed in the Rear Panel.

Turn off the switch: Remove all power cords from the power inlets.

The Rear Panel displays the rear panel location of power supplies and fabric modules.

The switch uses power cables with IEC-320 C-19 plugs. The accessory kit provides IEC-320 C-19 to C-20 power cables, each two meters long. To insert a power cable, plug the power cables into the inlet.

The -48V and Battery-Return leads are a pair and should run adjacent and be approximately the same length.

Le - 48V et câbles de batterie-retour sont une paire courir à côté de l'autre et doivent être à peu près la même longueur.

Before installing, remove power from DC circuits by turning off the power line servicing the circuits. Prepare the stranded wiring before you begin a DC power installation.

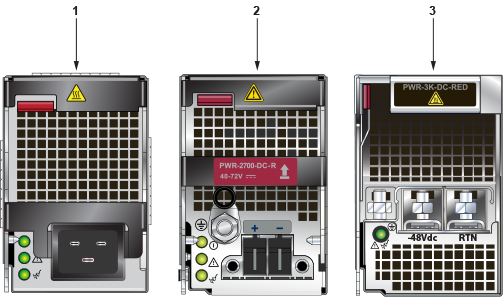

| 1 | Status LED | 3 | Ejector | 5 | -48V terminal |

| 2 | Ground terminal | 4 | RTN terminal |

The Figure 5 displays the PWR-2700-DC-R power supply without the DC adapter.

| 1 | Ground |

The Table 1 table shows the power supply specifications for each of the PSUs supported.

| Power Supply | Maximum Output Power Rating (DC) | Input Voltage and Frequency | Maximum Input Current | Input Branch Circuit Protection |

|---|---|---|---|---|

| PWR-2700-DC-R | 2600 W | -48 or -60 V (nominal) | 80 A | 100 A |

| PWR-3K-DC-RED | 3000 W | -48 or -60 V (nominal) | 80 A | 100 A |

| PWR-3KT-AC RED | 3000 W | 200 to 240 V (nominal) 50 - 60 Hz (nominal) | 16 A | 20 A |

The Table 2 table shows the power supply configurations for the modular switches.

| Modular Switch | Recommended Number of PSUs (for redundancy) | Number of PSUs Shipped in Bundle | Minimum Number of PSUs Required (per power domain) | Maximum Number of PSUs Supported | Number of Power Domains |

|---|---|---|---|---|---|

| DCS-7504N | 4 | 4 | 2 | 4 | 1 |

| DCS-7508N | 6 | 6 | 2 | 8 | 1 |

| DCS-7512N | 8 | 8 | 2 | 12 | 1 |

| DCS-7516N | 12 | 12 | 3 | 20 | 2 |

Installation of this equipment must comply with local and national electrical codes. Consult with the appropriate regulatory agencies and inspection authorities to ensure compliance if necessary.

Installation de cet équipement doit être conformes aux codes électriques locaux et nationaux. Si nécessaire, consulter les organismes de réglementation appropriés et des autorités de contrôle pour assurer la conformité.

Read all installation instructions before connecting the system to the power source.

Lire toutes les instructions d'installation avant de brancher le système à la source d'alimentation.

Most installations will have redundant, dual, independent power feeds.

For supervisor cooling purposes, all systems require a minimum number of operating power supplies (see Power Supply Configurations) at all times in the top half of the chassis. For optimal performance, alternate pairs of power supplies (A and B) evenly from top to bottom (8 or more slot chassis).

Each power supply includes a fan that maintains proper power supply temperature and cools the supervisor modules. The appendices display the location of the components on all switches described in this guide.

The Front Panel displays the front panel location of the supervisor modules.

The Rear Panel displays the rear panel location of power supplies and fabric modules.

This unit requires over-current protection.

Cet appareil nécessite de protection contre les surintensités.

Unused slots must be occupied or covered with a blank to ensure proper airflow through the chassis.

Les emplacements inutilisés doivent être occupés ou recouvert d'un blanc pour assurer la bonne circulation d'air dans le châssis.

Supervisor modules contain console, management, and USB ports. Figure 6 and Figure 7 display port locations on the supervisors.

| 1 | Status LED | 5 | Fan module status LED | 9 | Active LED |

| 2 | USB ports | 6 | Fabric module status LED | ||

| 3 | Ethernet management ports | 7 | Linecard status LED | ||

| 4 | Serial console port | 8 | Power supply status LED |

| 1 | Status LED | 5 | Clock input port (optional) | 9 | Power supply status LED |

| 2 | USB ports | 6 | Fan module status LED | 10 | Active LED |

| 3 | Ethernet management ports | 7 | Fabric module status LED | ||

| 4 | Serial console port | 8 | Linecard status LED |

| 1 | Status LED | 5 | Clock input port (optional) | 9 | Power supply status LED |

| 2 | USB ports | 6 | Fan module status LED | 10 | Active LED |

| 3 | Ethernet management ports | 7 | Fabric module status LED | ||

| 4 | Serial console port | 8 | Linecard status LED |

The DCS-7516-SUP supervisor cards must be installed in one of the two designated slots in the DCS-7516N switch, as shown in Figure 9.

| 1 | Supervisor slot 1 |

| 2 | Supervisor slot 2 |

| RJ-45 | DB-9 | RJ-45 | DB-9 | |||||

|---|---|---|---|---|---|---|---|---|

| RTS | 1 | 8 | CTS | GND | 5 | 5 | GND | |

| DTR | 2 | 6 | DSR | RXD | 6 | 3 | TXD | |

| TXD | 3 | 2 | RXD | DSR | 8 | 4 | DTR | |

| GND | 4 | 5 | GND | CTS | 8 | 7 | RTS | |

Install required SFP, SFP+, QSFP+, QSFP100, and CFP2 optic modules in linecard module ports (Figure 10).

Connect cables as required to linecard module ports or fixed MPO ports. Supervisor and linecard module ejectors on the front of the chassis assist with cable management.

Excessive bending can damage interface cables, especially optical cables.

Flexion excessive peut endommager les câbles d'interface, en particulier les câbles optiques.

When bypassing ZTP, initial switch access requires logging in as admin, with no password, through the console port. Then, you can configure an admin password and other password-protected usernames.

This manual configuration procedure cancels ZTP mode, logs into the switch, assigns a password to the admin, assigns an IP address to the management port, and defines a default route to a network gateway.

The rack mounting procedure is identical for the 7504N and 7508N Series switches. Illustrations in this chapter depict the mounting of an unpopulated 8-slot chassis.

The 7512N and 7516N switches only require a different mounting shelf for the four-post rack. Illustrations in this chapter depict the mounting of an unpopulated 12-slot chassis and a 16-slot chassis.

After completing the instructions for your rack type, proceed to Cabling the Modular Switch.

To mount the switch to a two-post rack, assemble mounting brackets to the middle of the chassis, then attach the brackets to the rack. The switch does not support a front or rear mount into a two-post rack.

The switch is mounted onto a four-post rack by assembling a shelf into the rack and then placing the switch on the shelf.

Illustrations in this section depict the mounting of an unpopulated 8-slot chassis.

The Figure 4 display the front four-post mounting parts. The Figure 5 display the rear four-post mounting parts.

The following discusses the rack mounting assembly procedure for the 7512N and 7516N Series switches.